Ever wondered how renewable energy projects stay efficient, safe, and profitable year after year? The answer lies in a robust operations and maintenance framework. This post dives deep into the comprehensive O&M framework for the eight REA-EEP 3 projects. You’ll discover standardized procedures, maintenance schedules, and performance tracking methods that ensure operational excellence, safety, and sustainability. Ready to explore how these strategies can transform your renewable energy ventures?

Why Operations and Maintenance Matter for Renewable Energy

Renewable energy plants, like those with photovoltaic systems and battery storage, demand constant care. Neglect leads to downtime, reduced output, and costly repairs. Organized framework tackles these challenges head-on. It covers eight projects with shared components, including battery energy storage systems, PV plants, and SCADA networks. This consistency boosts efficiency and sets a benchmark for the industry.

- Maximize Asset Value: High performance ratios and system availability drive energy yield and financial returns. For example, targeting over 98% annual availability keeps plants productive.

- Ensure Safety: Strict adherence to OSHA and NFPA standards protects workers and equipment. Zero safety incidents remain the goal.

- Promote Sustainability: Proper waste management aligns operations with renewable energy missions.

- Achieve Excellence: Data-driven decisions and skilled teams optimize resources.

- Extend Lifespan: Preventive maintenance reduces unexpected failures, saving money long-term.

The Core Components of the Framework

The REA-EEP 3 projects for example share key elements. Understanding these components helps you grasp the framework’s scope.

- Battery Energy Storage Systems (BESS): Store excess energy for later use, requiring daily monitoring of charge and health.

- Photovoltaic (PV) Plants: Generate power from sunlight, needing regular cleaning and inspections.

- Inverters: Convert DC to AC power, with quarterly checks to ensure efficiency.

- Mounting Structures: Support PV arrays, inspected quarterly for stability.

- LV Panels and MV Switchgears: Manage electrical flow, tested annually for safety.

- Transformers: Step up voltage, monitored daily via SCADA.

- Support Buildings: House equipment, checked monthly for structural integrity.

- SCADA Systems: Provide real-time data, audited annually for reliability.

Safety First: Protecting People and Assets

Safety underpins every operation. The framework mandates compliance with OSHA, NFPA 70, and UL 9540 standards. Regular audits keep practices current.

- Personal Protective Equipment: Workers wear safety glasses, hard hats, and arc-rated clothing daily.

- Emergency Plans: Drills prepare teams for electrical fires or BESS thermal runaway.

- Environmental Care: Hazardous materials get proper disposal to avoid contamination.

Imagine a scenario where a quick response to a fault prevents a major incident. This proactive approach saves lives and equipment. How prepared is your team for emergencies?

Performance Tracking: Measure to Improve

Data drives success. The framework uses key performance indicators to monitor progress.

- System Availability: Aim for over 98% uptime annually. A plant running 99% of the time generates more revenue.

- Performance Ratio (PR): Compare actual output to theoretical maximum. Higher ratios signal better efficiency.

- Mean Time Between Failures (MTBF): Longer intervals mean reliable equipment. Target maximization.

- Mean Time To Repair (MTTR): Faster repairs reduce downtime. Aim for lower times.

- System Downtime: Limit to under 440 hours yearly. Every hour counts.

- Safety Incidents: Strive for zero incidents. Training plays a key role.

SCADA systems collect this data in real time, enabling quick adjustments. What metrics matter most to your operations?

PV Plant Maintenance: Keeping Panels Powered

PV modules need regular attention to maintain output. The schedule balances frequency with thoroughness.

- Daily: Check string performance via SCADA. Spot anomalies fast.

- Monthly: Walk through arrays to assess soiling and damage.

- Quarterly: Clean with de-ionized water to avoid scratches.

- Annual: Test with I-V curve tracing to identify weak modules.

Mounting structures get quarterly visual checks and annual audits. Inverters require daily SCADA monitoring and annual electrical tests. These tasks take 20-40 hours yearly per component. How often do you inspect your PV systems?

BESS Maintenance: Power Storage Done Right

Battery energy storage systems demand meticulous care. Daily BMS monitoring tracks charge and temperature.

- Monthly: Inspect for cracks or leaks in battery modules.

- Quarterly: Balance voltages and use thermal cameras.

- Annual: Test capacity with controlled cycles.

BESS inverters and thermal management systems follow similar schedules, with 30-50 hours annually. A well-maintained BESS can last decades. Are your batteries getting the attention they deserve?

Electrical Systems: Ensuring Stable Power

LV panels, MV switchgears, and transformers keep the grid humming.

- LV Panels: Daily checks catch issues early. Annual tests ensure safety.

- MV Switchgears: Monthly monitoring includes gas pressure checks. Annual calibrations refine performance.

- Transformers: Daily SCADA data prevents overloads. Bi-annual oil analysis spots wear.

These tasks take 20-40 hours yearly. A transformer failure can halt operations. How do you monitor your electrical infrastructure?

SCADA and Communication: The Nervous System

SCADA systems and communication networks link everything together.

- Daily: Verify data points display correctly.

- Monthly: Update software and review logs.

- Annual: Audit cybersecurity and calibrate sensors.

Communication checks ensure reliable data flow. Annual audits take 35-45 hours. A glitch here disrupts everything. How robust is your data network?

Building Infrastructure: A Solid Foundation

Support buildings protect equipment and people.

- Monthly: Inspect roofs and walls for leaks.

- Annual: Assess foundations and clear drains.

Safety systems like fire extinguishers get quarterly checks. A secure building boosts morale. What condition are your facilities in?

Preventive vs. Corrective Maintenance

Two strategies keep plants running.

- Preventive Maintenance: Daily SCADA checks evolve into annual overhauls. This prevents 80% of failures.

- Corrective Maintenance: Fault reporting triggers structured repairs. Spare parts management minimizes delays.

A root cause analysis after a failure improves future reliability. Which approach dominates your maintenance plan?

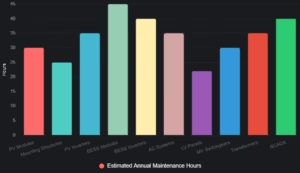

Equipment Maintenance Timelines

Each component has a tailored schedule.

- PV Modules: 25-35 hours yearly.

- Mounting Structures: 20-30 hours.

- PV Inverters: 30-40 hours.

- BESS Modules: 40-50 hours.

- BESS Inverters: 35-45 hours.

- AC Systems: 30-40 hours.

- LV Panels: 20-25 hours.

- MV Switchgears: 25-35 hours.

- Transformers: 30-40 hours.

- SCADA: 35-45 hours.

Total hours vary by project size. Does your schedule match this intensity?

Continuous Improvement: A Living Framework

The manual updates with field feedback and regulations.

- Training: Staff learn new procedures regularly.

- Integration: SCADA ties data to actions.

- Audits: Regular checks ensure compliance.

Lessons learned refine practices. How do you adapt to new challenges?

Your Path to Operational Excellence

This framework offers a blueprint for success. It balances safety, efficiency, and sustainability across eight projects. You can adopt these practices to boost your renewable energy output.

Start with daily SCADA monitoring. Add quarterly inspections. Track KPIs to spot trends. A plant hitting 99% availability outperforms competitors. What will you implement first?